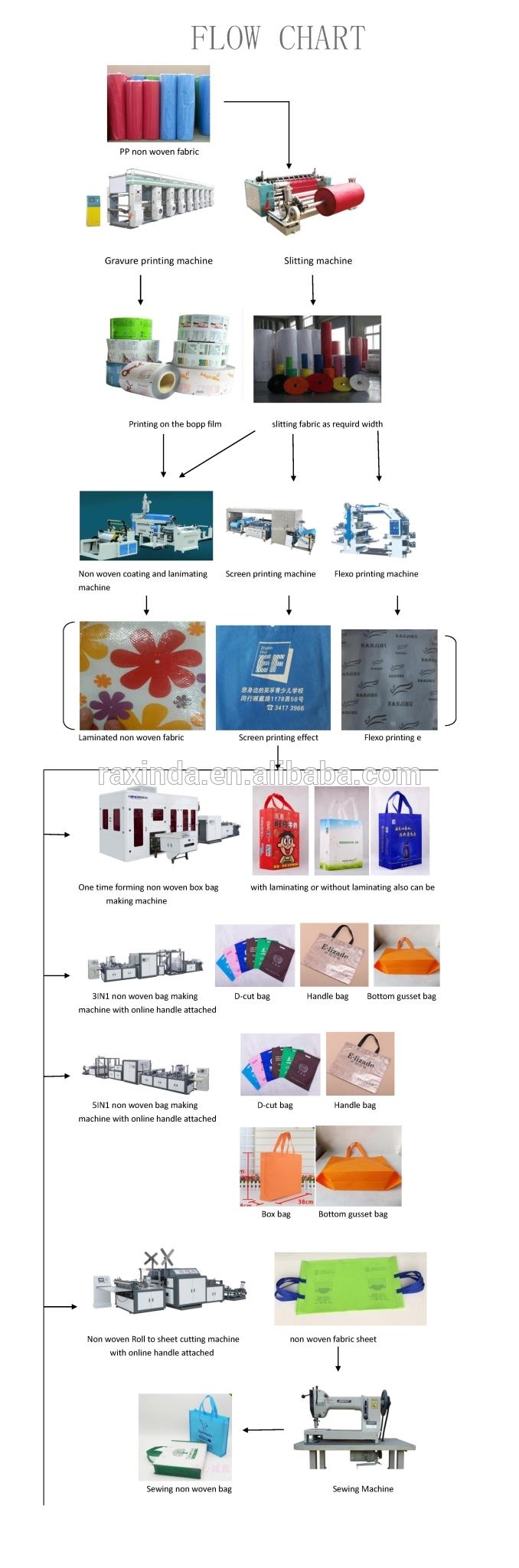

Non Woven Fabric Manufacturing Machine

1.Main introduction

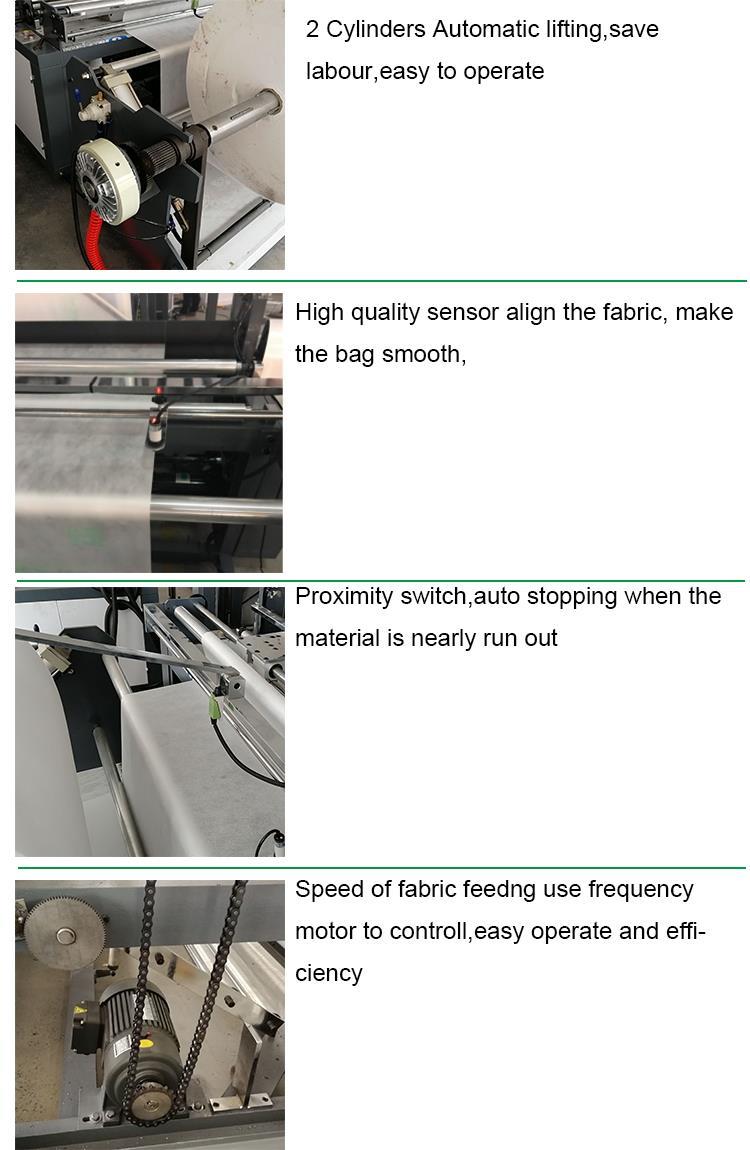

This equipment can make non-woven three-dimensional bag and peace pocket, put the materialusing automatic tension and automatic correction system, after feeding using frequency conversion motor, synchronization controlby main motor, to maintain stable and constant tension, the bag is neat and beautiful, the bottom of the heat seal using triangular ultrasonic, stepper motor drive pressure roller bag indentation, so that the bag is stronger and easy to fold. The machine is fast and easy to operate. With automatic stop, automatic counting, synchronous drilling and other functions.

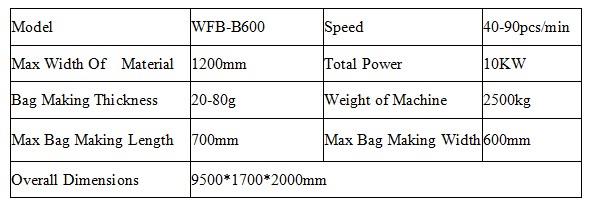

2.Main Specifications and Equipments

3.Detailed

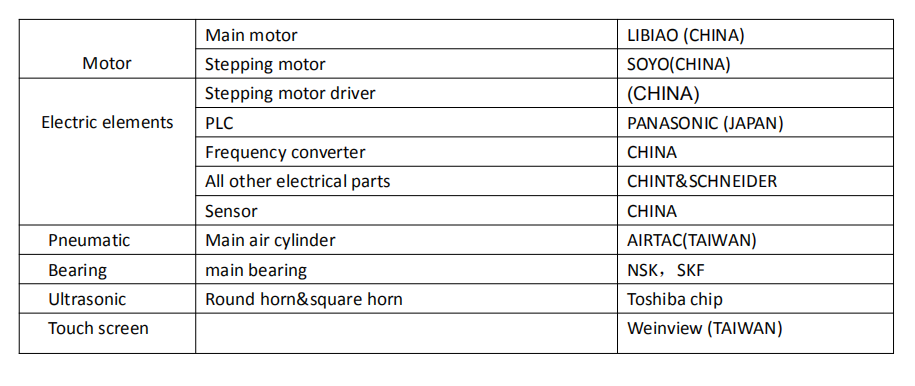

4.Main components

5.Service

1.Engineers provide overseas installation services,Until customers are familiar with independent operating machines.

2.24 hours maintenance hotline service to ensure the smooth production of customers.

3.Give away the right amount of vulnerable parts free of charge.

4.You can enjoy a 5% discount on your first purchase.

5.100 percent quality assurance.

6.Provide full production line.Such as Printing Machine,Non-woven Fabric Making Machine.

How about the maintance and aftersales service?

Our engineer available service overseas, and we can provide remote control service and online service forcustomers. But costomer has to be responsible for the accommodation and transportation costs of the technical staff.

6.Advantage

A:The feeding rack is lengthened, and the maximum diameter of feeding is 20% larger than that of similar equipment, so as to reduce the feeding times and save the feeding time.

B:The length of the fuselage is 10% shorter than that of similar equipment, which reduces the tensile force in the traction of the cloth and the waste generated by debugging.

C:The ultrasonic welding head pressure adopts spring shock absorber, so the welding pressure is more even and the heat sealing effect is better.

-

Call Us>>Customer provide specification or sample.

-

Sample Confirm>>Colorido provide sample for cusotmer approval.

-

Order Confirm>>Order confirmed and proceed.

-

Production>>Bulk production QC inspection.

-

Shipping>>Final QC inspecition and Export.

-

Commitment>>Colorido is responsible to all quality issues.

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Can make the bag as follow one time

Associate machine

Main non woven machine