Automatic Non woven Zipper Bag Making Machine

1.Performance and Characteristics

This machine adopt mechanical and ultrasonic sealing technology, is a kind of ideal equipment for non woven bag making, can produce various bag such as zipper bag, D-cut bag ,wall calendary bag.

1. Micro-computer control

2. Stepping motor (servo-motor control system can be selected and equipped)

3. Arbitrarily fixed length

4. Accurate and stable photocell tracking

5. Stop automatically when the label lost

6. Automatic punching, automatic counting and alarm

Automatic thermostats, perfect and smooth sealing, with EPC control

2.Main Specifications and Equipments

| Model | WFB-ZP800 |

| Max. Width of Material | 800mm |

| Max.bag-making width | 780mm |

| Max.bag-making length | 100-500mm |

| Material thickness range | 20-80g |

| Production Speed | 40-70 pcs/min |

| Power | 8kw |

| Overall Dimensions | 7500*1500*1800mm |

| Weight | 2000kg |

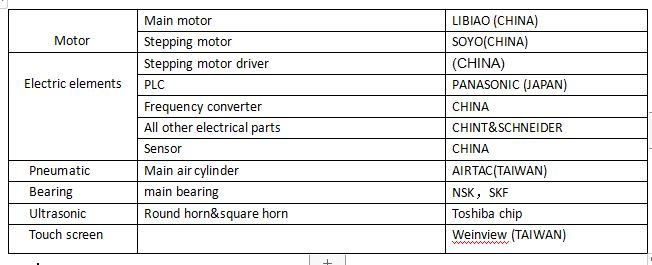

3.Main components

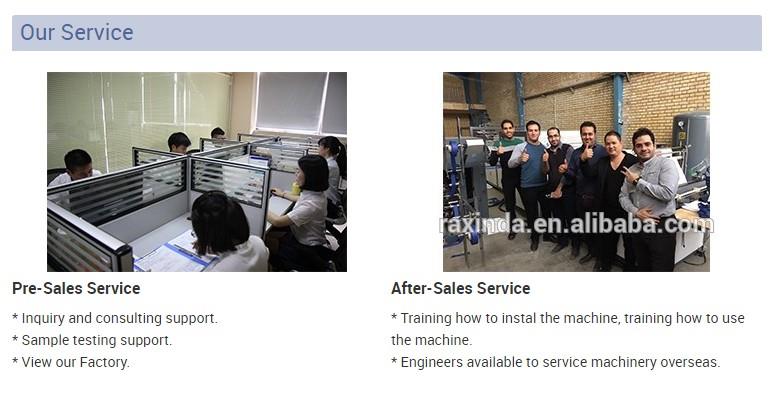

4.Service

4.Service

Delivery time:

-within 70days after receivedpayment

-Loading port:NingboPort/Shanghai Port

-Destination port: The port at your option

Packing and Marking :

– Packing: Export and Sea-worthy standard

Quality of Goods:

-100% newmachine

5.Advantage

- We arespunbond fabric making machinemanufacturer and exporter;

- We have professional team for machine design/produce/install and training service;

- We can provide complete turn-key project for all of clients;

- We offerS,SS,SSS,SMS,SMMSnon woven fabric production line with effective fabricwidth 1600mm,2400mm,3200mm;

- Wehad been passed CE and ISO Certification in past few years;

- Wegainedgood reputationnot onlyin China but also in other countries;

- We havenearly 100 set ofprojects inChinaand overseas.

such asSaudi Arabic,Turkey,Thailand,Malaysia,Russia,Morocco,Lebanon,Korea,Brazil…

- We insist on”High Quality;Good Service” so We are High&Good;

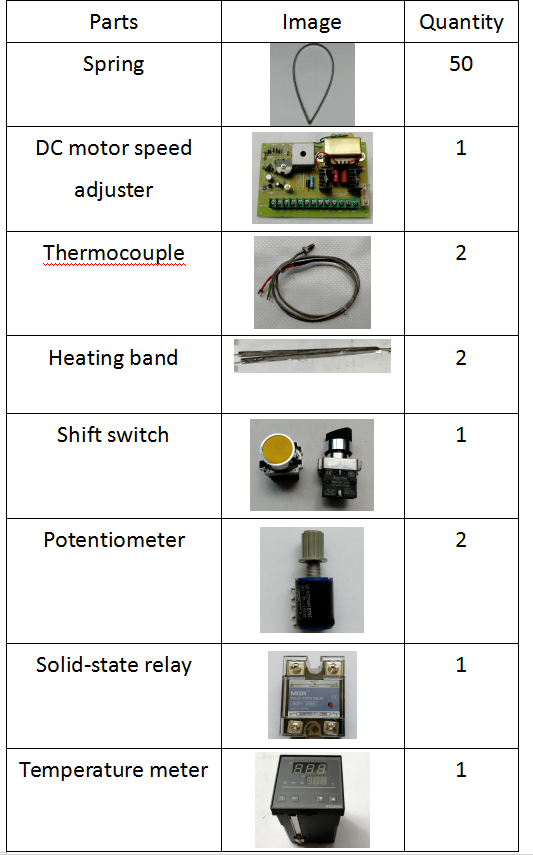

6.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

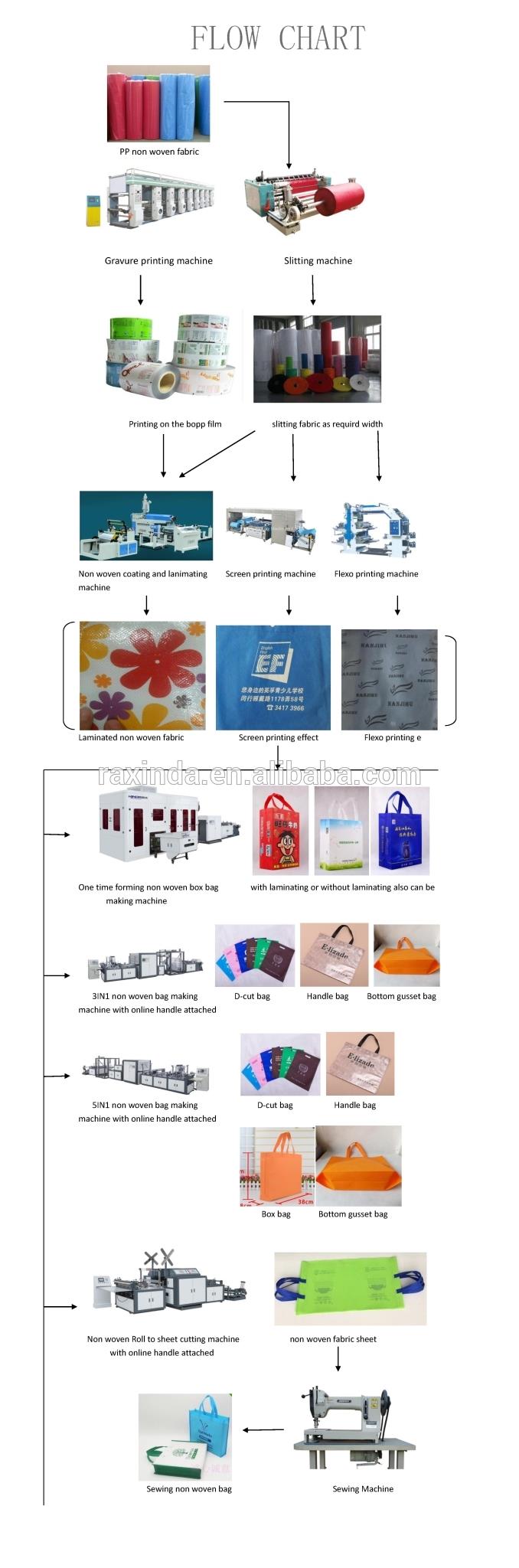

Associate machine

Main non woven machine

Bag sample

Bag sample

Fine quality management pay attention to every detail of the equipment manufacturing process

We have established stringent spare parts quality management standards, some key spare parts use well-known foreign brands to ensure he high performance of each machine, low figure rate, durability, simple and convenient operation and maintenance, every detail from the customer’s consider the angle